Technology could drive down costs and boost performance of lithium-ion batteries used in cellular phones, tablets, electric vehicles and industry.

Vancouver, B.C. – September 26, 2012 – Vancouver-based Perfect Lithium Corp. is on the verge of perfecting a novel processing technology for all present and future high-energy-density cathode materials that will drive down costs and boost the performance of lithium-ion batteries typically used in portable electronics such as cellular phones and tablets, as well as in electric vehicles and industrial energy storage applications.

Dr. Teresita Frianeza-Kullberg, Co-CEO and CTO of Perfect

Lithium Corp., displays the product of their innovative process,

a nano-structured lithium-ion cathode material that improves

the performance of lithium-ion batteries.

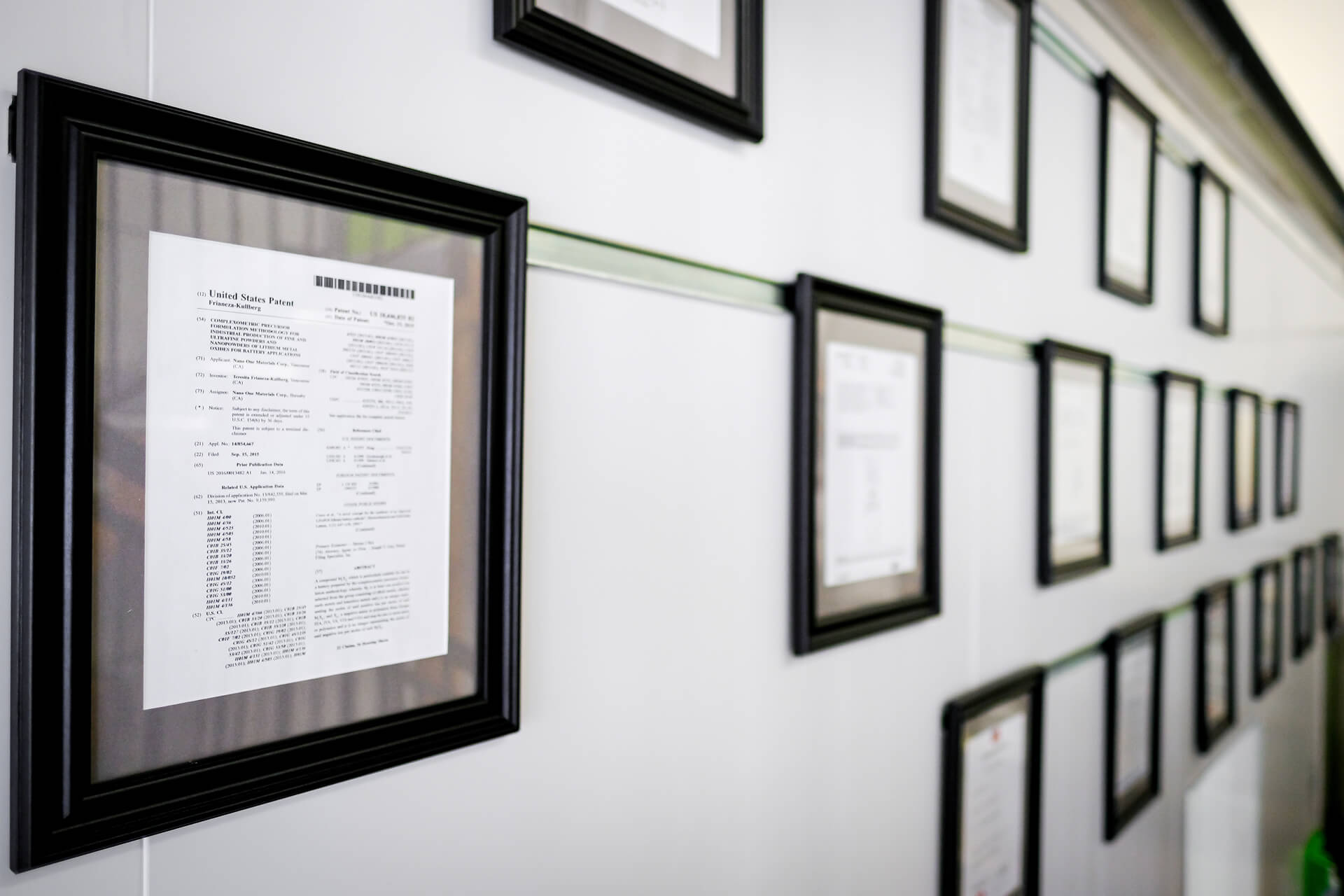

Dr. Teresita Frianeza-Kullberg, a 30-year veteran of industrial lithium chemistry who has contributed significantly to the success of lithium giants Chemetall Foote Corp., FMC Corp. and Lithium Corp. of America, has partnered with engineer Dan Blondal and Vancouver entrepreneur and financier John Lando to bring her novel processing technology from the lab bench to the manufacturing room floor. Dr. Kullberg, who is now co-CEO and Chief Technology Officer of Perfect Lithium, has been awarded over 25 patents for lithium materials and processes that increase performance and cost efficiency.

“Dr. Kullberg has a reputation for valuable, commercially viable lithium technologies,” said Dr. Jon Hykawy, who has a professional interest in the lithium markets as Head of Global Research, Clean Technologies and Materials Analyst for Byron Capital Markets Ltd. in Toronto. “I believe that there is a very good possibility of this going to market and actually being adopted by manufacturers. This could disrupt the global lithium supply chain.”

Batteries are essentially limited by the capabilities of the energy storing metals that go into them. Perfect Lithium has developed a cost reducing method of producing these materials that store more energy for all conceivable formulations of cathodes and anodes – the positive and negative terminals of a battery that carries ions between the two electrodes through the electrolyte.

“Most other battery researchers are working on new chemical formulations” added Dr. Hykawy. “Perfect Lithium is improving the underlying preparation methods for all formulations of cathodes and anodes.”

The traditional solid state synthesis method used to produce battery electrode materials typically involves incremental steps of crushing, grinding, milling, blending and heating lithium and other metals into fine powders, which can take four to five days. Perfect Lithium’s chemical synthetic method of blending and preparing lithium-ion materials uses standard equipment found in the chemical, food, pharmaceutical and cosmetic industries, lending itself to continuous flow production and cutting processing production times down to as little as one day. Perfect Lithium’s process also leads to a unique nano-structure in the material that enables electrolytes to penetrate deep into the material and amplify capacity, energy density and the flow of ions.

At Perfect Lithium’s research facility in Charlotte, North Carolina, the Company is already confident in its scalable approach. Perfect Lithium has produced kilogram sized batches of cathode powders that measure 15 to 30 per cent higher energy densities than commercial grade materials. The faster process could potentially cut manufacturing costs in half. Additional testing in 2012 is expected to yield further gains in energy density as well as processing cost reductions.

“The Perfect Lithium team has identified a sweet spot in the lithium space where incumbent processing methods leave a large opportunity on the table,” said Dan Blondal, Co-CEO of Perfect Lithium Corp. “The Company’s objective is to establish its technology as the de facto manufacturing standard for making all lithium-ion cathode materials. We believe that our technology can realistically reduce the cost per kilowatt hour by 20 to 40 per cent for existing and emerging lithium-ion cathode material formulations.”

In lithium-ion batteries, the cathode is the most expensive active component comprising 23 per cent of the cost of battery cells and 11 per cent of typical electric vehicle batteries, according to a research report by Deutsche Bank. A recent Yano Research Institute report projected that the global lithium ion battery market could reach $37 billion by 2015 and the cathode market alone could reach $6.5 billion.

About Perfect Lithium Corp.

Perfect Lithium Corp. is a Vancouver-based company dedicated to producing the highest performance lithium-ion materials using novel and cost-effective methods that are scalable for manufacturing. The Company is developing and commercializing a patented chemical synthetic process for producing lithium-ion cathode materials that significantly reduces the cost of processing and enables the use of lower grade raw materials while producing industrial scale, high performance nano-structured particles for all cathode formulations. Perfect Lithium was founded by Dr. Teresita Frianeza-Kullberg, John Lando and Dan Blondal in 2011. Headquarters are located in Vancouver, Canada and laboratory facilities are located in Charlotte, North Carolina.